Table of Contents

Kognitwin Simulation¶

Welcome to the Kognitwin Simulation documentation. This documentation covers all aspects of the simulation platform.

Documentation Sections¶

| Section | Description |

|---|---|

| Always-On Model | Learn about the always-on simulation model |

| Simulation Dashboard | Overview of the main simulation dashboard |

| What-If | Running what-if scenarios |

| Integration with Kognitwin | How simulation integrates with Kognitwin |

| Trending | Working with trend data |

| Unit Profiles | Managing unit profiles |

| Download Simulation Files | Downloading simulation project files |

| Admin Portal | Administration portal guide |

Always-On Model¶

The Always-On Model represents the physical asset as close as possible. It consumes time-series data through the common Kognitwin Time-Series Endpoint to define boundary conditions (e.g. Battery Limits of the simulated process scope, Valve Positions, Controller Setpoints etc.).

The Always On model provides virtual sensors, realtime plant insights and generates snapshots, that can be used for What-If, Re-Play and Look-Ahead simulations.

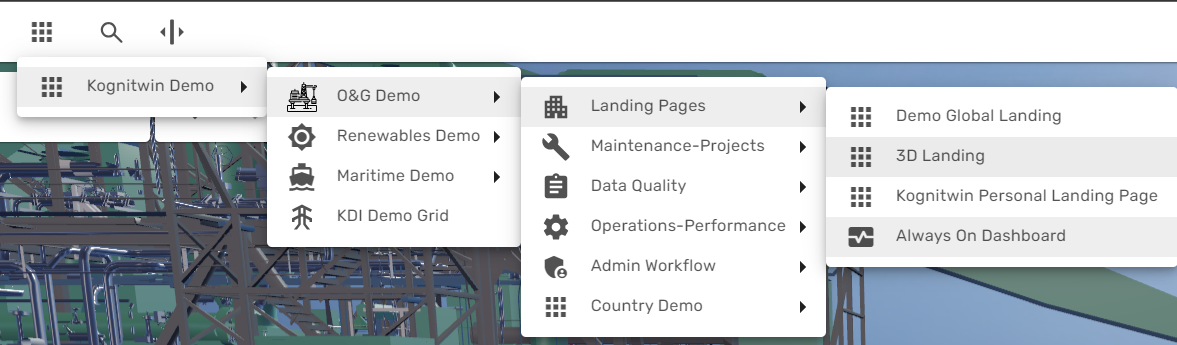

An overview for the main Always-On model instance is provided through the simulation dashboard. It is available from the main menu, typically called "Always On Dashboard":

If the simulation workflow is enabled in your environment, you can at any point open the right-click context menu for a specific object or tage (for example from 3D or from a P&ID) and fly to the corresponding tag in the Always-On Dashboard:

Simulation Dashboard Overview¶

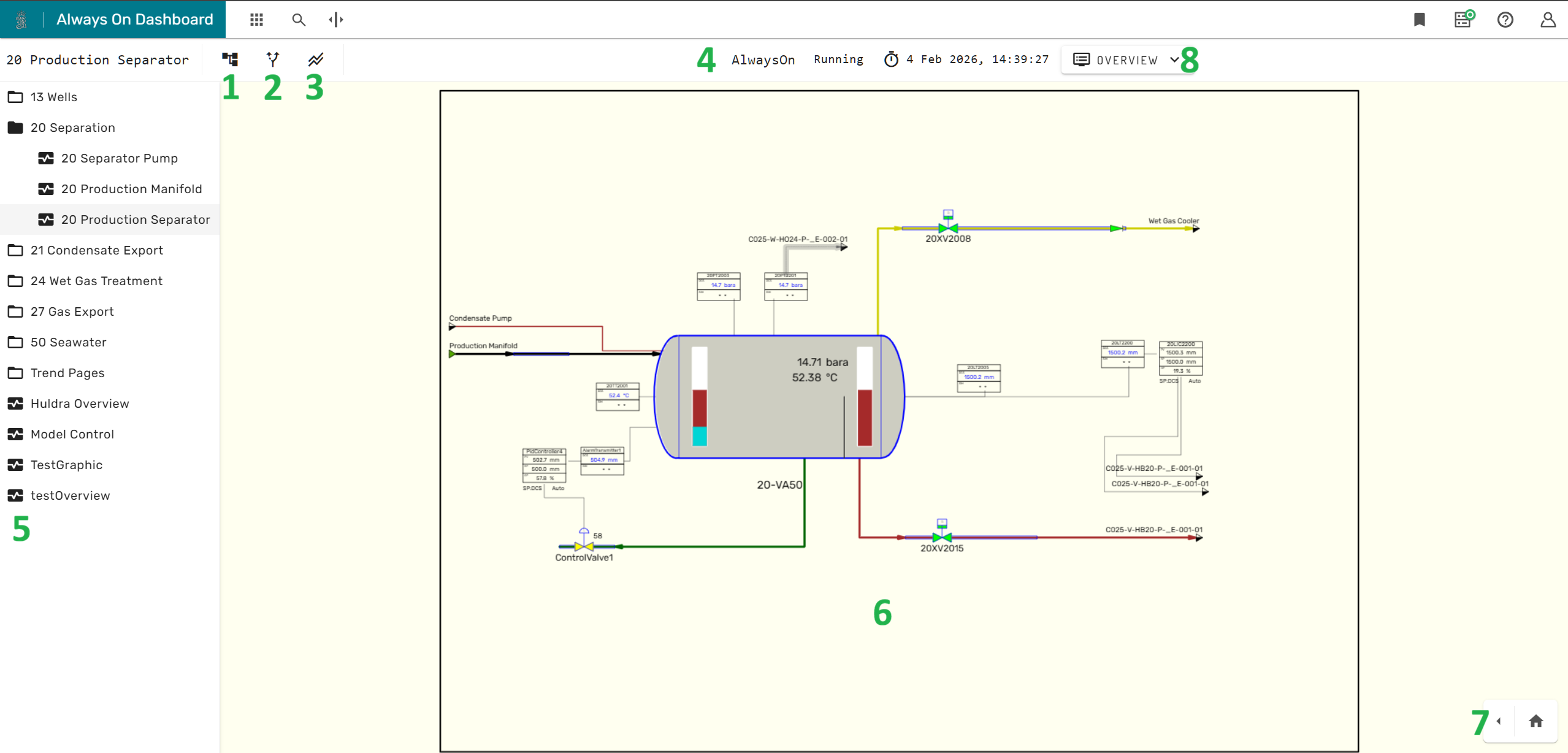

The Simulation dashboard is the main visualization component for integrated Simulations. It contains a rich set of functionality.

The tree structure icon 1 in the main menu bar shows or hides the process graphic navigation menu 5 on the left side of the screen.

The branching arrows icon 2 opens the What-If Simulation Panel.

The two parallel trend lines icon 3 opens the buffered trends menu.

In the central area of the main menu bar 4 provides status information about the simulation, as for example the running state, the current model time.

In the center of the simulation dashboard, the currently selected simulation graphic 6 is displayed.

In the lower right corner 7, the layer menu and the Unit Profiles can be expanded.

To the right of the main menu bar 8, the module overview menus can be accessed.

Simulation Graphics¶

Simulation graphics are generated in dedicated desktop software and can be uploaded to Kognitwin through the admin portal.

Simulation graphics can contain the following elements: - A frame with a background - Static text and dynamically updating text fields - Equipment symbols, representing physical or virtual equipment like pumps, valves, compressors and sensors - Connection lines, represent one of the following: - Pipes carrying process fluid (colored lines, color indicates the fluid type) - Cables conducting electricity (black lines) - Mechanical shafts, conveying kinetic energy (black lines) - Low-Voltage Cables conducting signals, e.g. measurement values or control signals (dashed black lines) - Logical states as ON/OFF, TRUE/FALSE (black lines that turn red/green based on the signal)

Equipment symbols provide both left-click interaction (open the module faceplate) and right-click interaction (open the Kognitwin context-menu). Many equipment symbols will also change their appearance based on the state of the equipment they are representing. Valves will for example be green in open position, grey in closed position and yellow in a partially open position.

Connection lines provide left-click interaction (open the stream dialog).

Navigating Simulation Graphics¶

The simulation dashboard provides the following ways to navigate between simulation graphics:

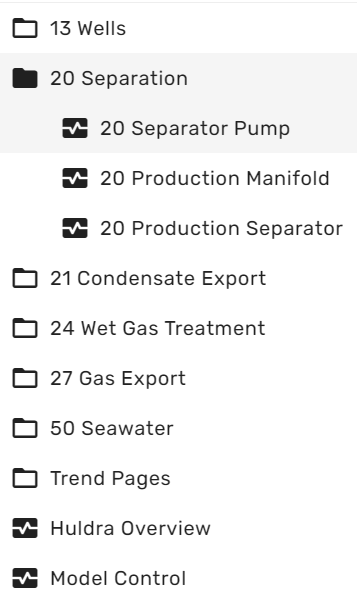

- The Simulation Graphic Navigator menu

- Stream Connectors

The Simulation Graphic Navigator can be expanded on the left side of the screen as described in the overview section. The simulation graphic navigator uses a tree like structure, branches can be expanded and deflated by clicking on the folder icon. The actual simulation graphics are represented by a small rectangle with a wave function plot. Left-clicking on a graphic icon will open the graphic in the main area of the simulation dashboard.

If connection lines connect signals or process fluid streams across multiple graphics, the two corresponding ends are connected through so called "stream connectors", which typically look like small triangles (arrow tips).

By left-clicking on a stream connector the connecting simulation graphic is opened in the main area of the simulation dashboard.

Module Faceplate¶

Equipment Symbols (e.g. pumps, transmitters, valves etc.) have dedicated, module specific faceplates.

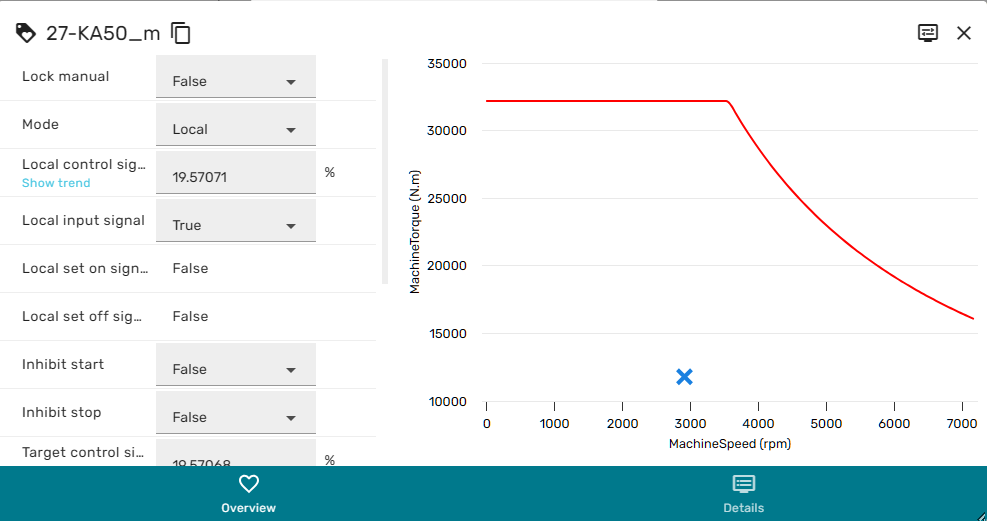

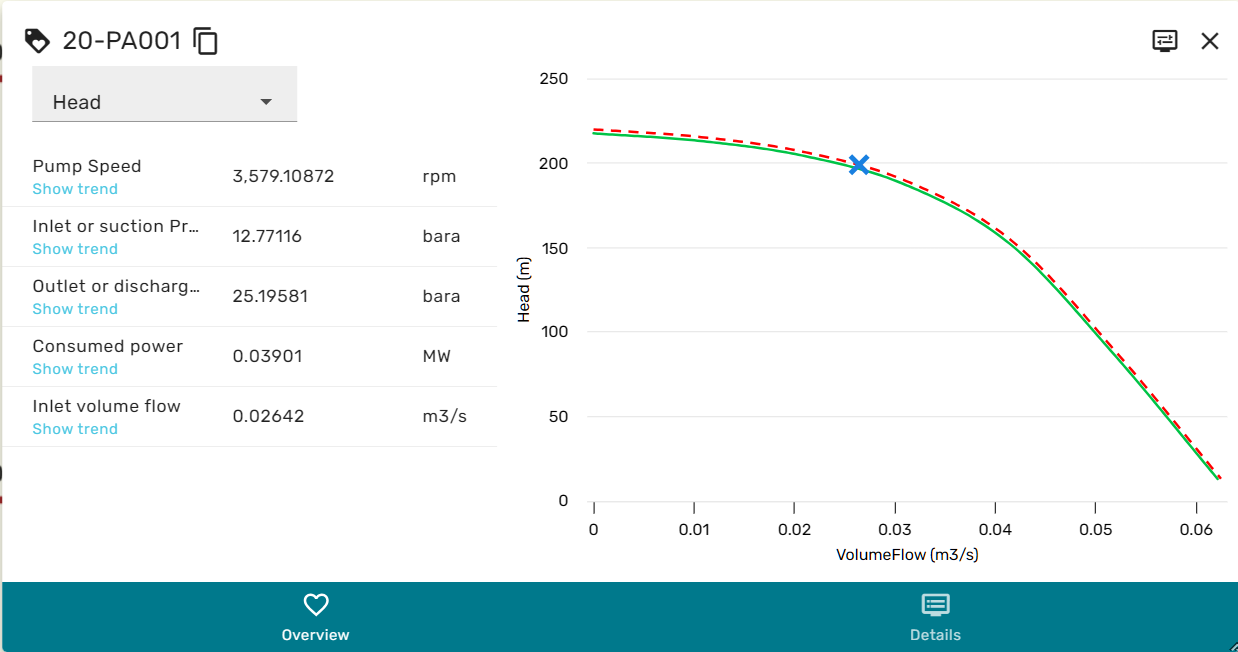

Facplates are generally build up from two main areas, the left area containing the most important variables and their current value, and the right area, that can depict a relevant trend or performance map for the specific equipment.

Facplates are generally build up from two main areas, the left area containing the most important variables and their current value, and the right area, that can depict a relevant trend or performance map for the specific equipment.

Some module faceplates also contain a drop-down menu at the top, which allows swapping out the plot or performance map in the right area.

The blue hyperlinks below the variables in the left area allow bringing up a trend for the corresponding variable. Sometimes, variables can have complex data-types that cannot be displayed as a number or text. In these cases, the variable value will become a hyper-link which opens a variable viewer on left-click.

Module Explorer¶

The Module explorer can be accessed in the following ways:

- From the icon in the upper right corner of module faceplates

- From the right click context menu

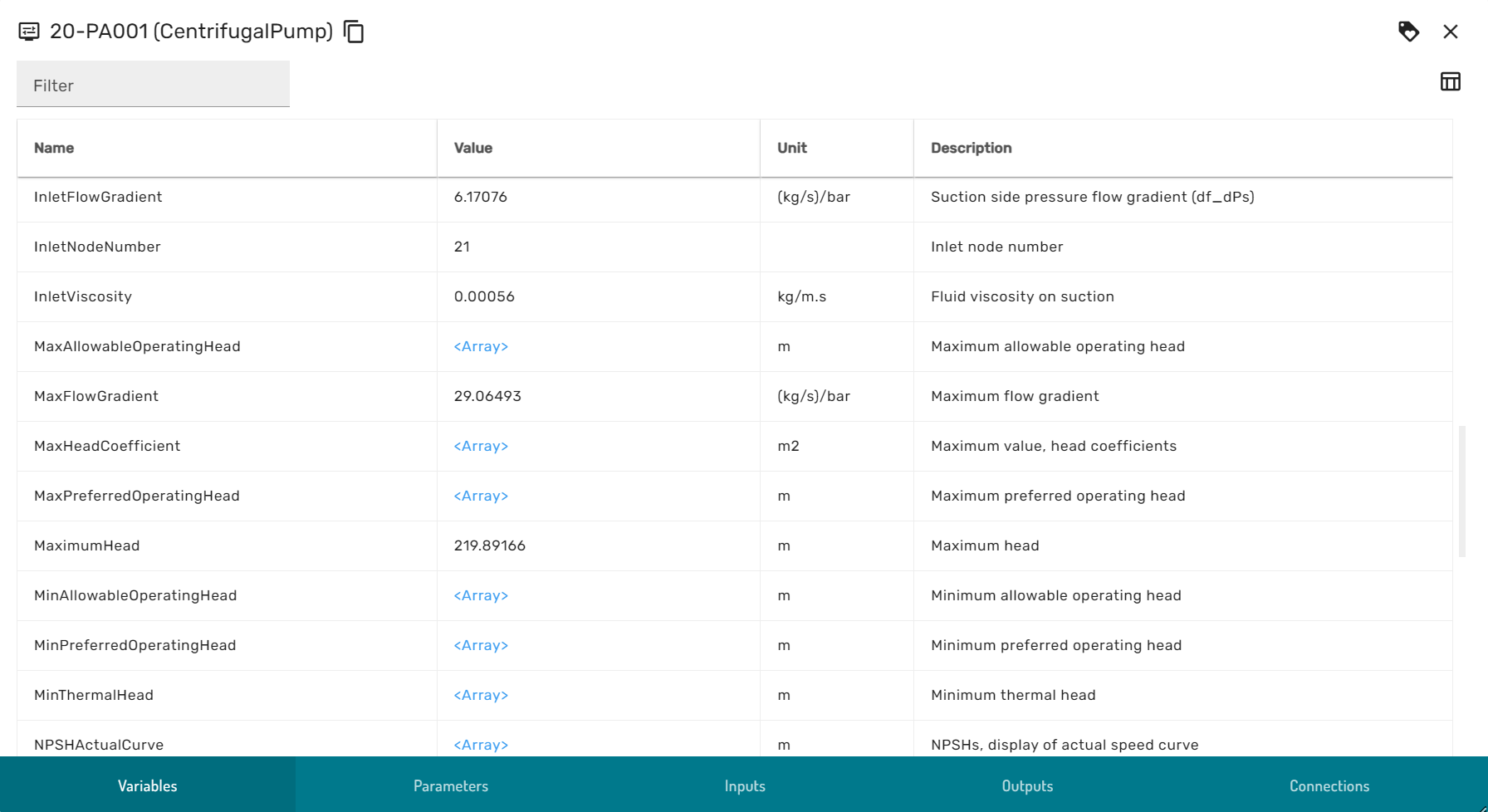

The module explorer is comprised of the following views, that can be swapped through the ribbon menu at the bottom of the dialog:

- Variables: Contains variables that are used internally by the simulator

- Parameters: Contains variables that define the physical and logical properties of equipment, for example design parameters or signal behavior rules

- Inputs: The variables that serve as the input to every simulation calculation step, for example process streams, boundary conditions and signal inputs

- Outputs: The variables that are calculated at every simulation calculation step, the results of the simulation.

- Browse Connections, further described in the browse connection dialog section

Stream Dialog¶

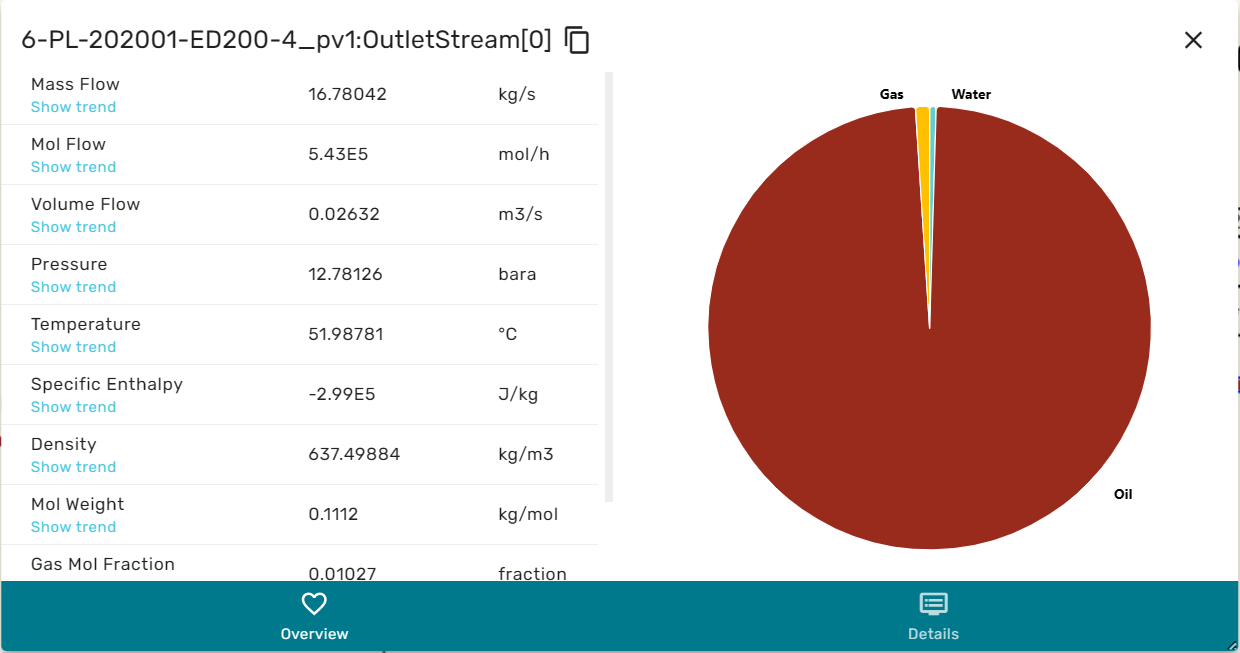

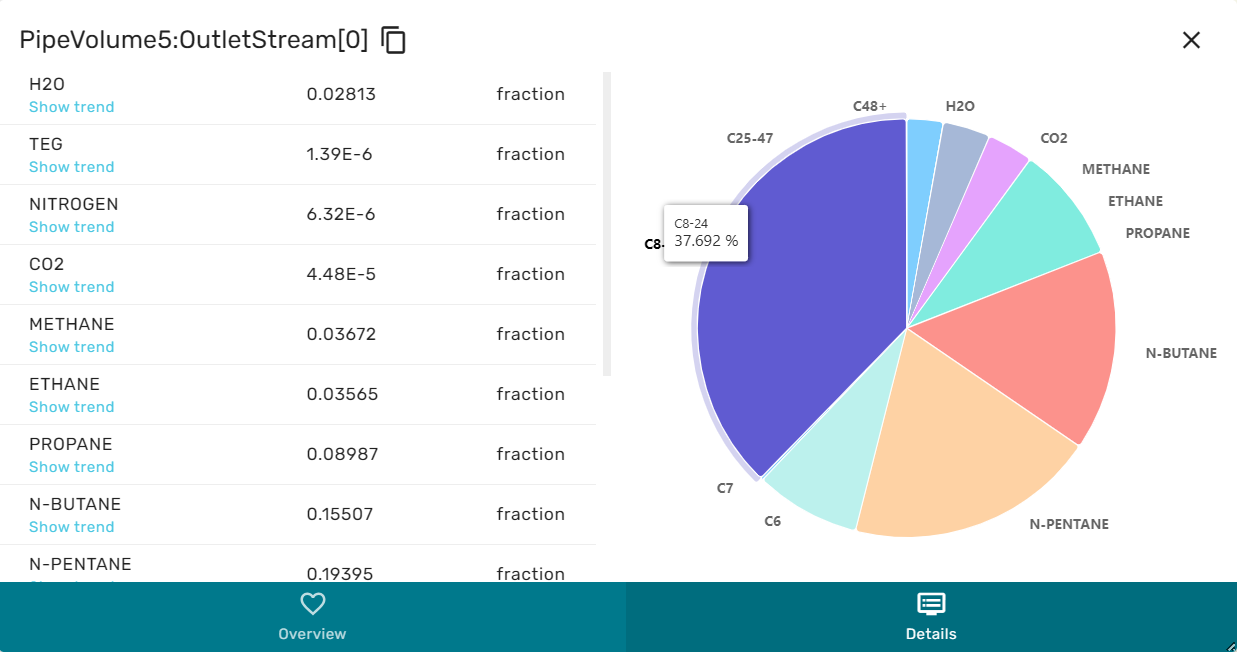

The Stream dialog is comprised of a left and a right area, and has an overview and a details view.

When in overview, the he left area contains a selection of the intensive and extensive thermodynamic properties of the stream, as for example massflowrate, temperature, enthalpy etc. The right area contains a cake diagram of the fluid phases (e.g. oil, gas water). By hovering the mouse over the cake diagram the numerical values for the phase fractions are displayed.

When in Details view, the left area shows a list of all chemical species that are contained in the stream and their concentrations. The right area then shows a cake diagram of the chemical composition. By hovering the mouse over the cake diagram the exact numerical values for molar concentrations are displayed.

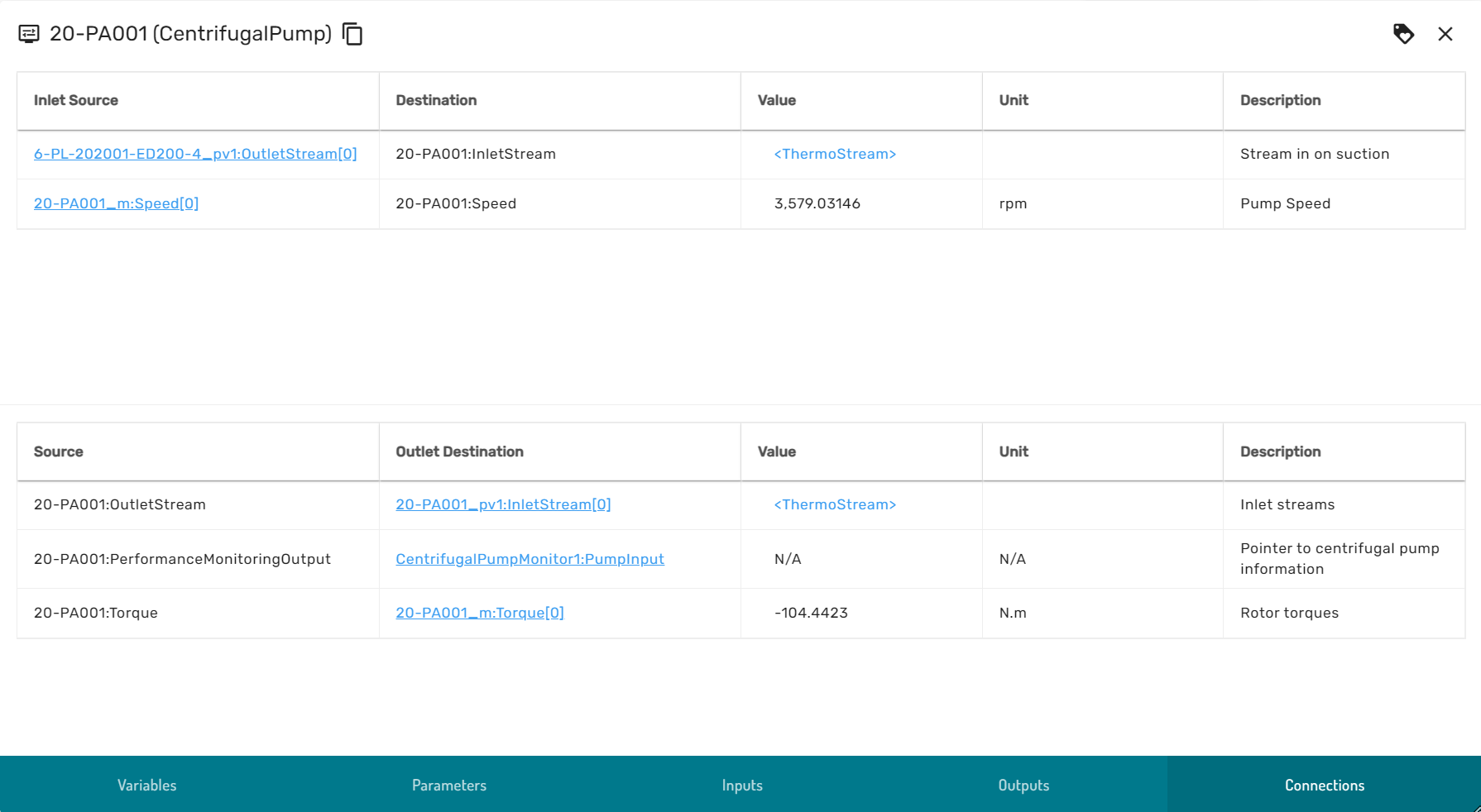

Browse Connection Dialog¶

The browse connection dialog allows users to explore the semantic topology of the simulation model. It shows all incoming and outgoing topological connections to and from a specific simulation module, and which variable they are connected to.

By clicking on the blue hyperlinks, the browse connection dialog traverses along the model topology graph to the adjacent incoming upstream module or subsequent downstream module. If a connection is of a primitive type (numeric, boolean or enumerator) the value of the connected variable is displayed, otherwise a hyperlink to the variable viewer is provided.

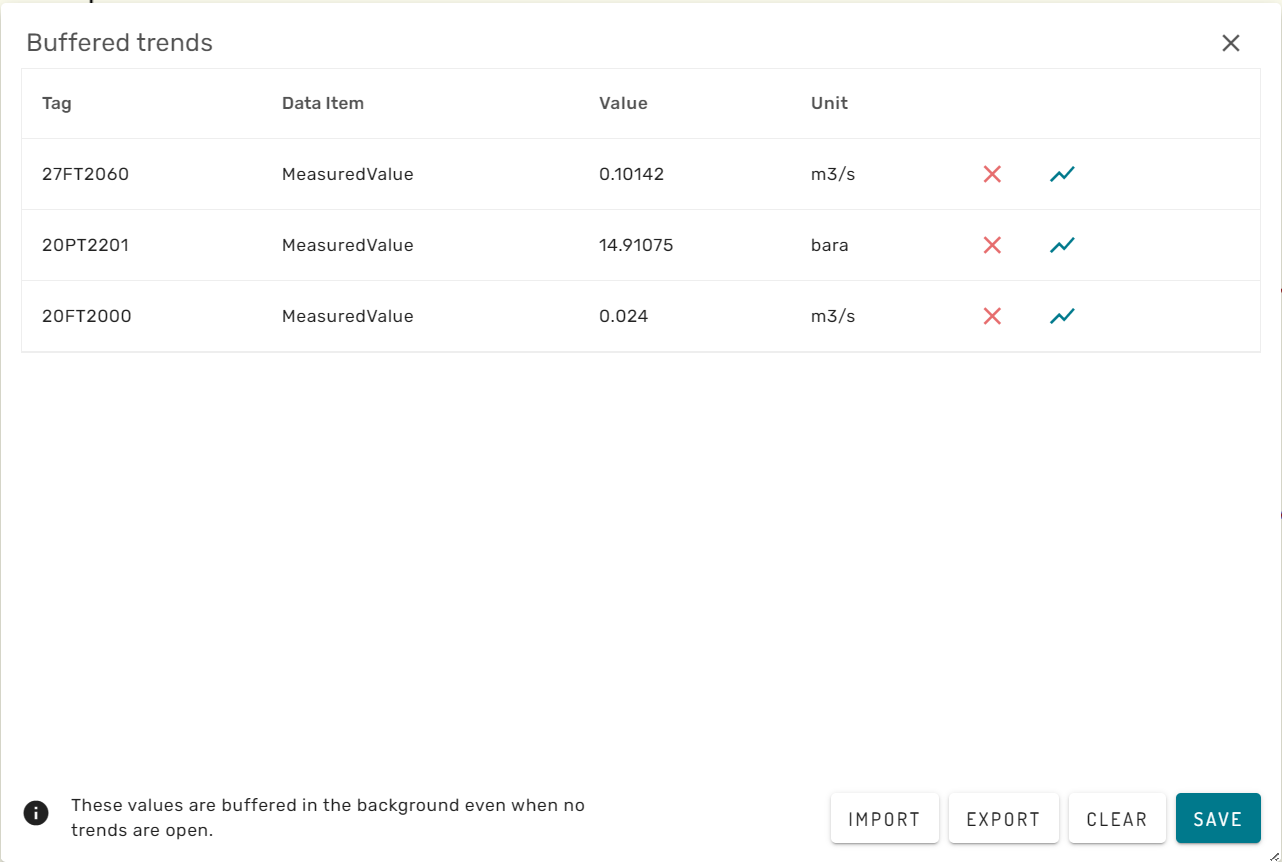

Buffered Trends¶

Simulations contain many variables and not all variables can be stored in the time-series database. Therefore, short-term time-series can be buffered in a browser session. When opening a trend for a variable that is not recorded in the time-series database, Kognitwin Simulation automatically adds the variable to the buffered trend variables.

The buffered trends overview menu gives a list of all buffered variables, as well as the possibility to extract a list with these variables, so that it can be restored at a later point in time or for a similar simulation (Import).

The red cross-mark behind a buffered variable will remove it from the browser caching. The blue trend icon will open the buffered trend for the specific variable.

The clear button removes all buffered variables from the browser session and clears the list.

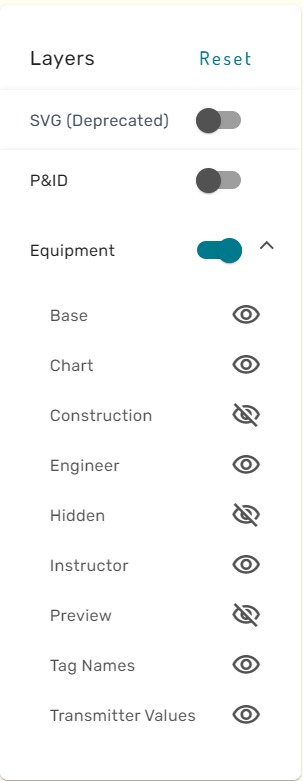

Layer Menu¶

The Layer Menu allows to show and hide different graphical features in the simulation graphic main view.

By clicking on the eye-icon, the respective layer can be shown or hidden. For certain graphics, a special "P&ID" layer is available. This layer contains the Process and Instrumentation Diagram that the simulation graphic has been built from.

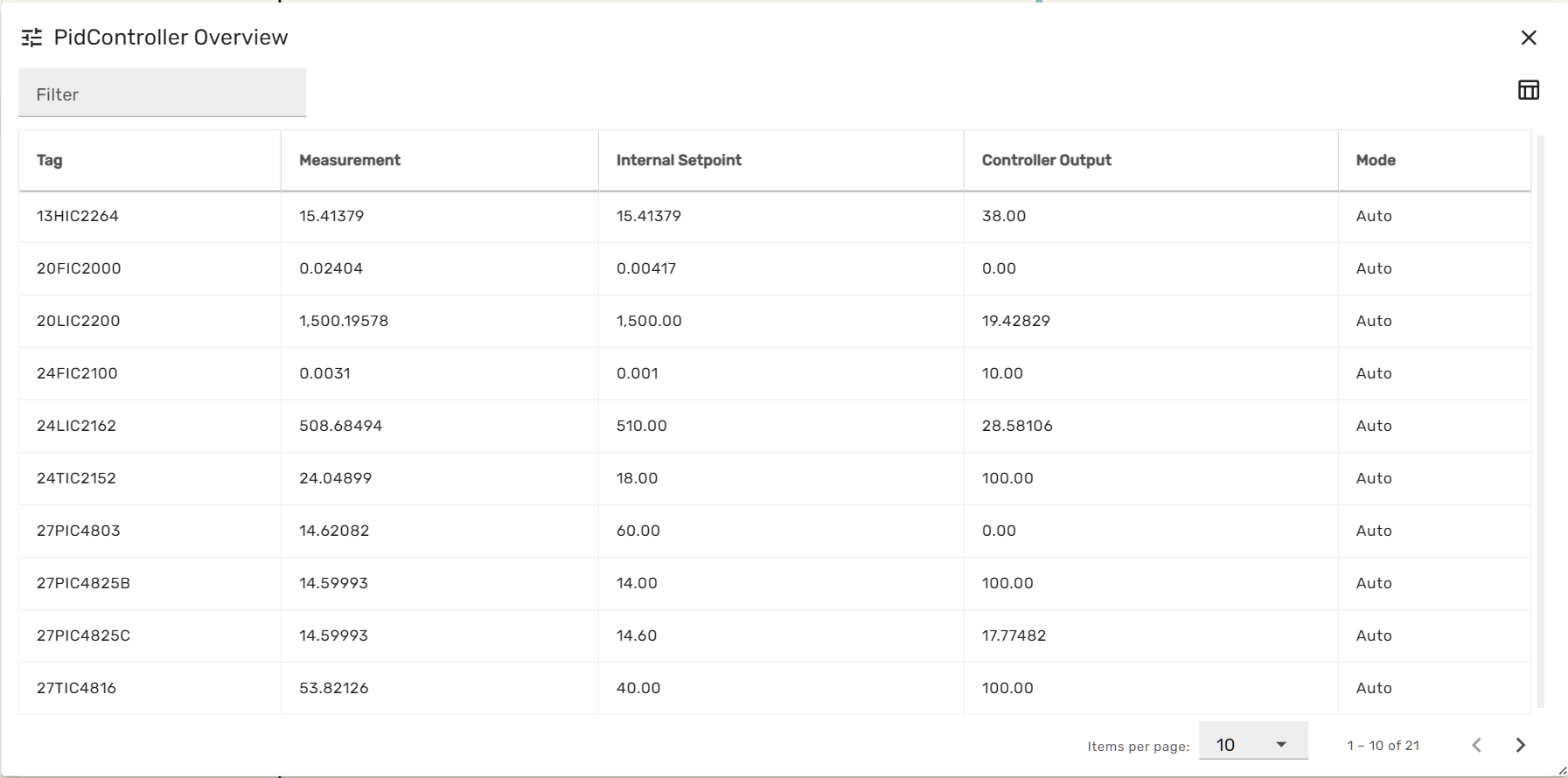

Model Overview Menus¶

Depending on the model content, different overview menus for specific module types (e.g. PID controllers, Replacers) are be available.

Each module overview menus list all modules of a specific type across the entire simulation model, together with some of the most important variables for this module type. The grey filter box in the upper left corner allows to enter a string, which will be applied as a filter on the module names. Thereby the list can be limited to selected entries.

When clicking on a row of the module overview table, the module-faceplate for the respective module opens.

Kognitwin Context Menu¶

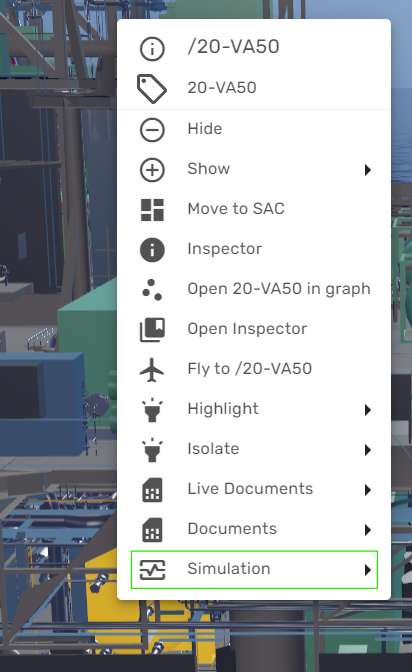

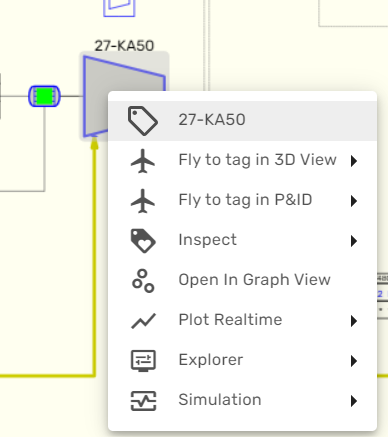

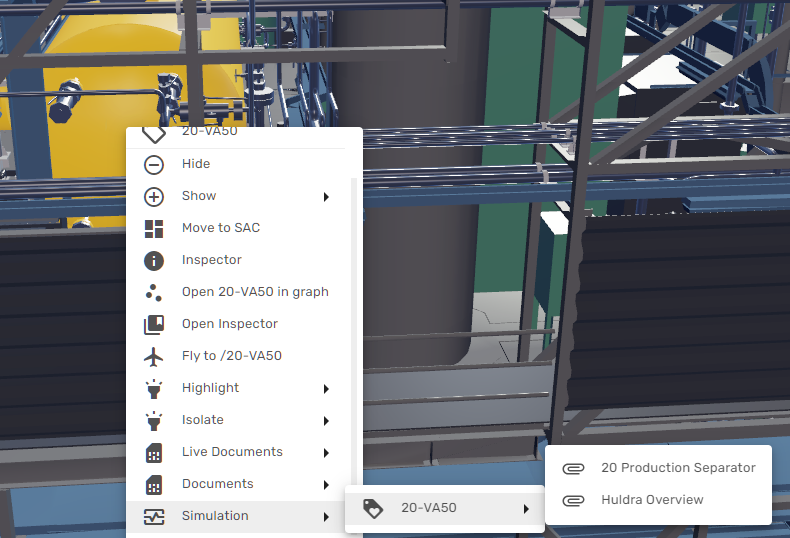

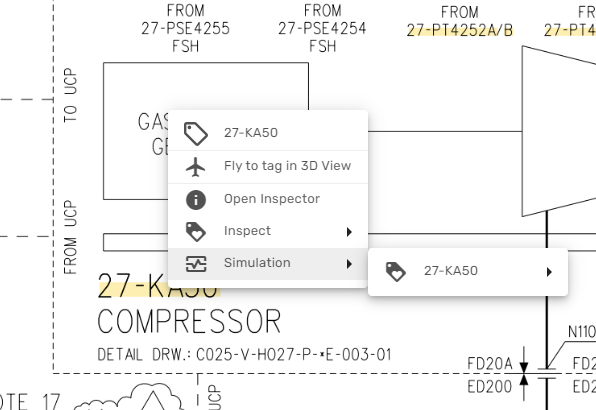

When right-clicking on a simulation module symbol, the Kogntiwin Context menu opens.

From here, the generic Kognitwin Tag explorer and all contextualized data for the simulated equipment can be accessed. Several entries allow to launch alternative workflows, as for example 3D visualization, the document viewer or the Kognitwin Graph View. From here, also the Module Explorer and all other Simulation graphics that contain the same module are available.

What-IF¶

A What-If simulation replicates the current state of the main Always-On simulation, but allows for user-controlled changes to both parameters and inputs, as well as controlling the simulation execution. Thereby, What-If simulations can be used to study alternative operating scenarios interactively.

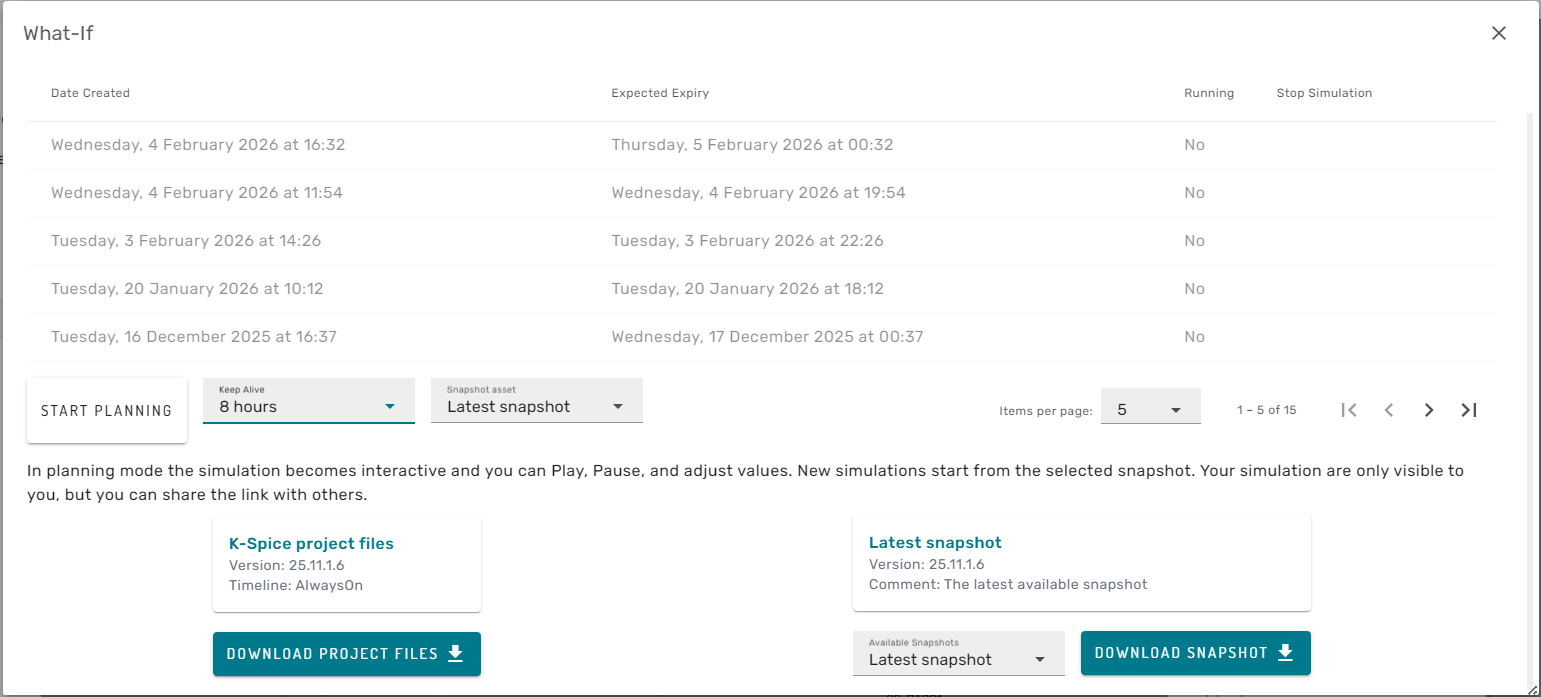

When pressing the two branched arrows from the Simulation Dashboard the what-if simulation dialog opens.

In the top of the dialog the user can se a list of active and expired What-If simulation instances. In the lower section of the dialog, the simulation project files and selected snapshots from the Always-On Simulation can be downloaded to the local computer, to enable on-prem What-If simulations in the corresponding desktop software (for example K-Spice Engineering).

In the central part of the Dialog a new What-If simulation instance can be invoked. For that, the user should first choose the time-of-life for the simulation (for example 8h) and which snapshot to start the simulation from (for example latest snapshot, or a snapshot from 3 days back). When pressing the "START PLANNING" button, a new browser tab will open for the new What-If simulation instance. It may take up to some minutes until the new simulation instance is ready for user-interaction. During this time the user will see a screen informing that the simulation instance is currently deploying:

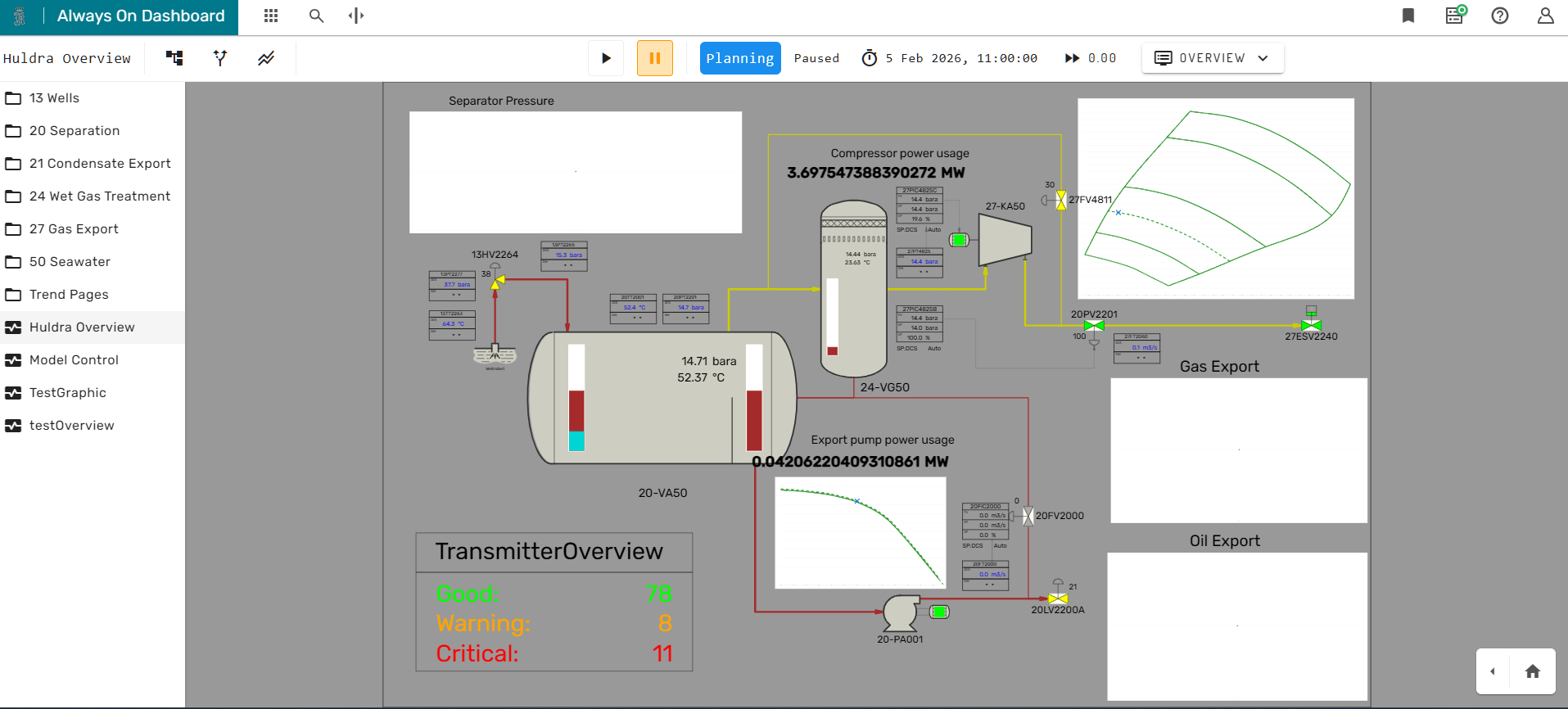

Once the simulation instance is ready for use, the Simulation Dashboard will show the home-graphic of the Simulation Project.

Controlling Model Execution¶

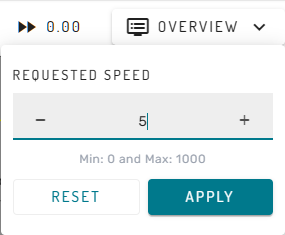

Once the What-If instance is ready, the main menu bar of the Simulation Dashboard provides altered functionality. The user can now start and stop model execution using the play and pause button. Furthermore, the target simulation speed can be changed by clicking on the number in the very right of the main menu bar. A new simulation speed can be set by using the + and - icons or by entering a number using the keyboard, and confirming the selection with the Apply button.

Controlling Model Behavior¶

In What-If Simulation mode, Faceplates, Stream Dialogs and similar can be opened as usual from the Simulation Dashboard.

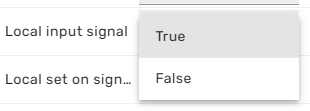

However, all writable inputs and parameters in Faceplates or other dialogs can now be modified by the user. This is indicated by the grey color of the value field:

By clicking on such fields, the user can set the new input to a new value.

The interaction happens in realtime and interactively, so it will depend on the model run state how fast changes of a certain input will have an effect on other process quantities.

Integration with Kognitwin¶

If the simulation workflow is enabled in Kognitwin, it can also be accessed from other workflows through the typical Kognitwin Context menus.

The following example shows how the simulation graphics can be reached from a separator in 3D, by using the right-click context menu:

In the same manner, the simulation can be accessed from live Process and Instrumentation Diagrams and other documents that have been contextualized in Kognitwin:

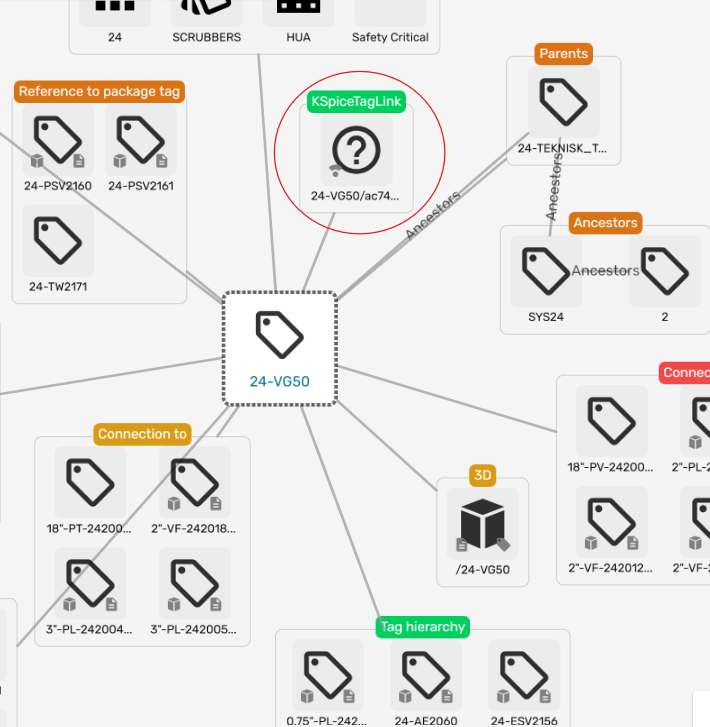

The user can also explore the exact tag relations using the Kognitwin Graph View. Here, the time-series tags produced by the Simulation show up as a separate collection item in the EDW tag view:

Trending¶

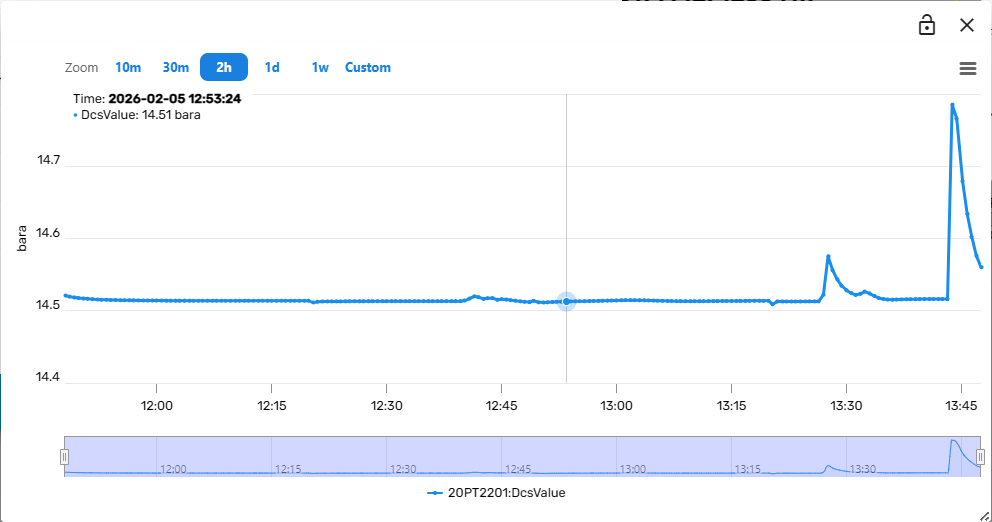

When simulating a facility, it is often interesting to monitor how the actual measurements in the field and the simulated variables behave over time. Therefore, the Simulation package includes a power trend component. Trends can be brought up from many places in the Simulation Dashboard by pressing on a "Show Trend" link.

The trend component contains controls to vary the observed time frame and to add other variables to the same trend plot.

When hovering over the trend-lines, the variable values at that specific point in time are displayed in a hovering overlay in the upper region of the trend component.

Change Observed Time Frame¶

There are multiple ways to change the time period that is being displayed in the trend plot. The first option is to drag the sliders in the miniature time-axis in the lower area of the trend component left or right. The entire observation window (translucent blue rectangle) can be moved back and forth in time by holding the left mouse button clicked and dragging the window left or right.

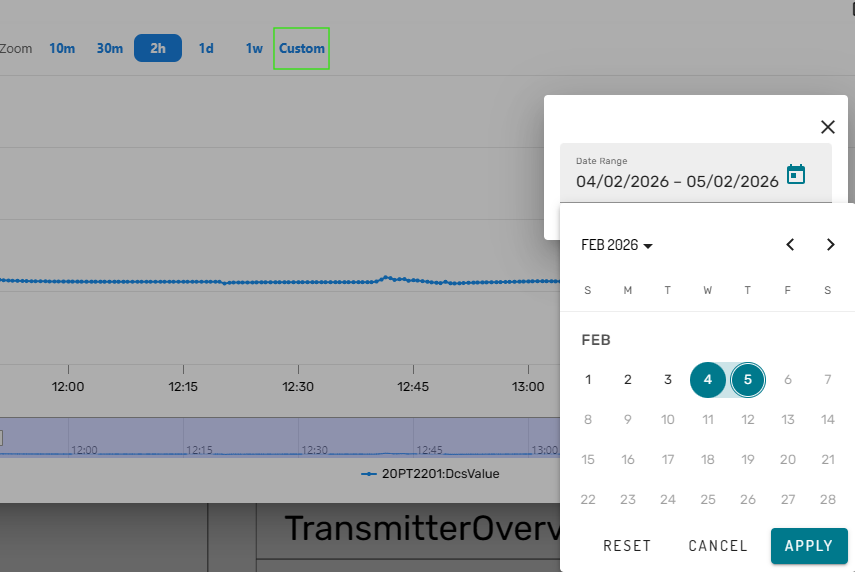

Alternatively, the user can pick one of the default options in the top of the trend component (e.g. past 10 minutes), or select a custom date range:

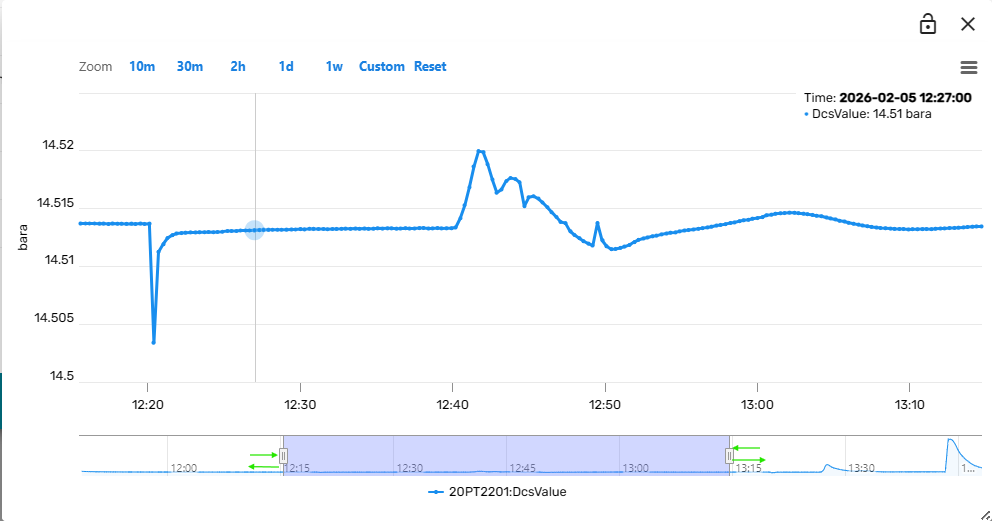

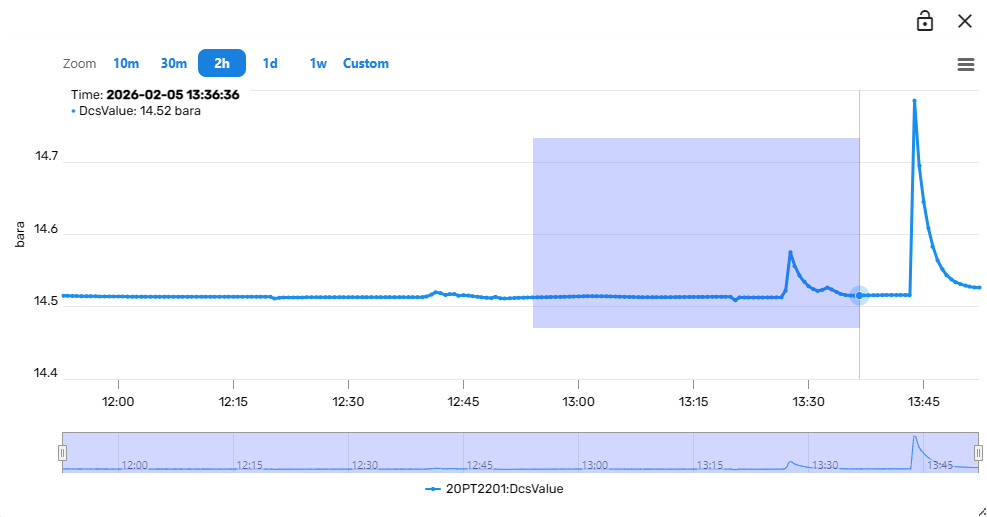

Additionally, it is at any time possible to zoom into the trend by dragging a rectangle within the actual trend plot:

The trend component will then zoom into the selected time-period and Y-Axis section.

Add additional variables to a Trend¶

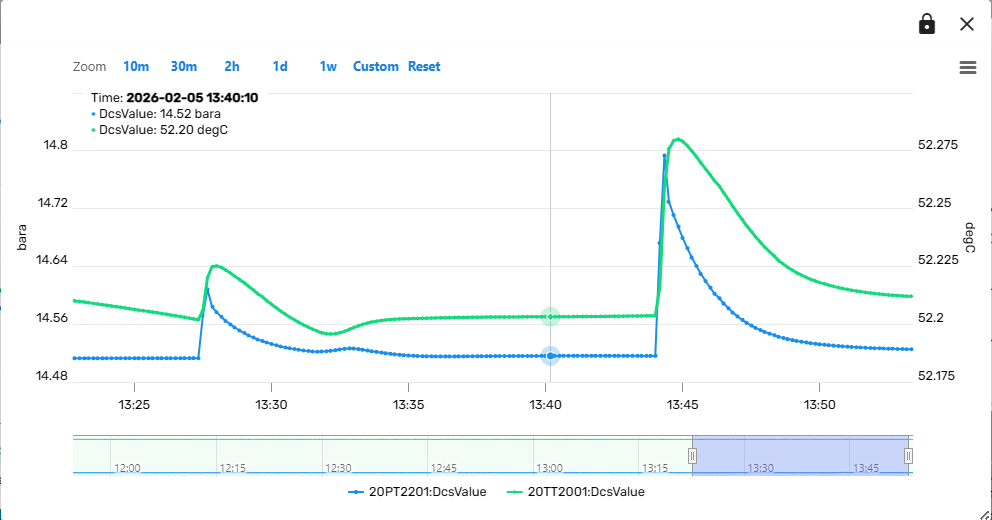

In many cases it will be useful to compare the trends of multiple variables within the same plot. This can be achieved by clicking on the lock symbol in the upper right corner of the trend component. Subsequently, clicking on a "Show Trend" link from the Simulation dashboard (for example from a Module Faceplate) will then add the variable to the existing trend instead of opening a new trend component. In this way, composite trends of multiple variables can be constructed interactively.

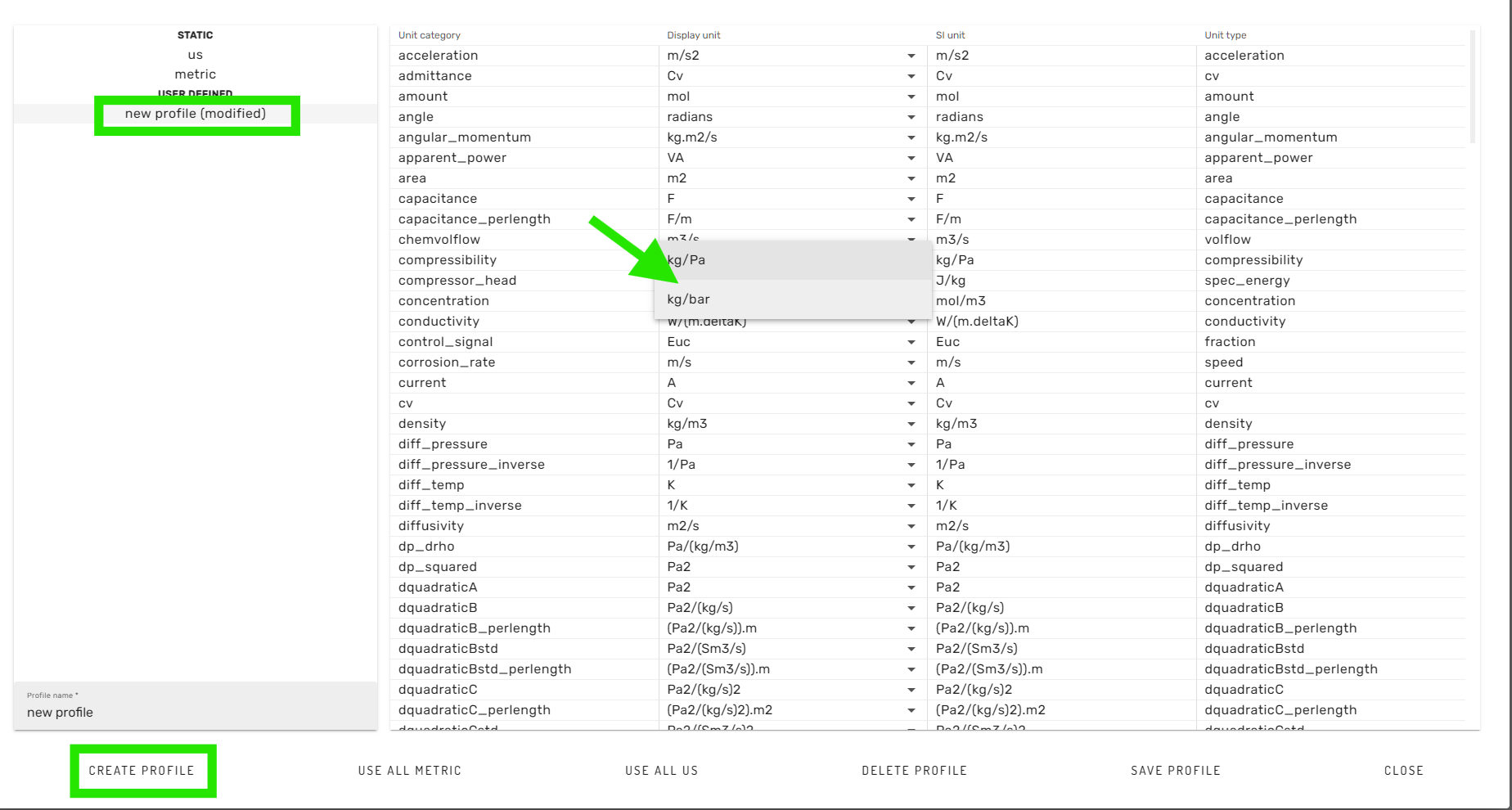

Unit Profiles¶

Values within the Simulation Dashboard can be viewed in different units. Every simulation workflow comes with a set of standard units, that are configured from the admin portal.

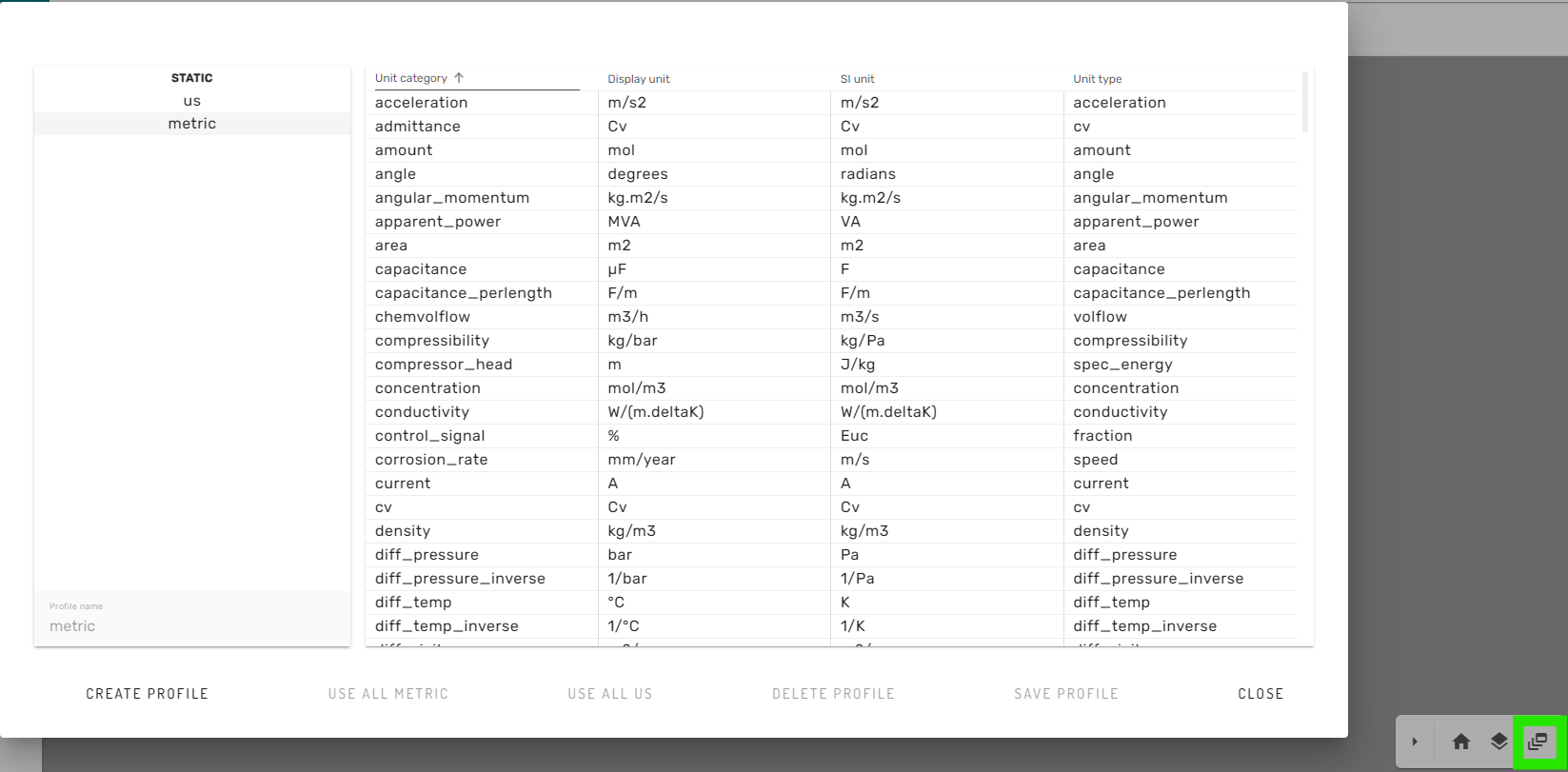

Users can at any point in time change the units they want to visualize data in, by opening the unit profiles dialog from the lower right corner in the simulation dashboard.

Here, the user can choose from a set of pre-defined unit-profiles (for example Metric or US units).

Furthermore, custom changes to the predefined unit-profiles can be made, when creating a new profile by clicking on the "CREATE PROFILE" button in the lower left corner. Then, the new profile can be selected in the list on the left hand side. Subsequently, changes can be made to the display units by using the dropdown dialogs for available units. Finally, the newly created unit profil can be saved with a new name, and is then available for the simulation workflow.

Downloading Project¶

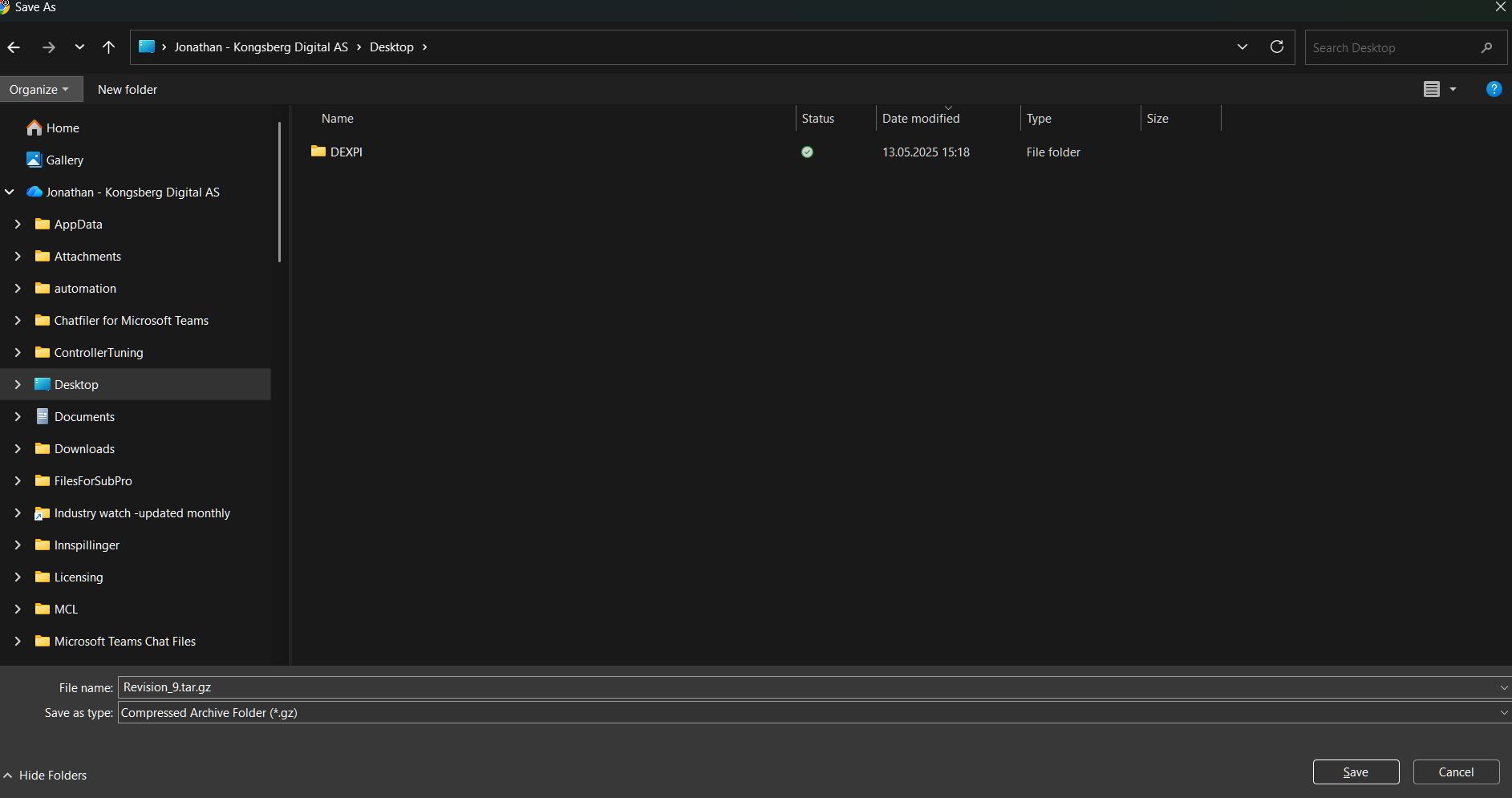

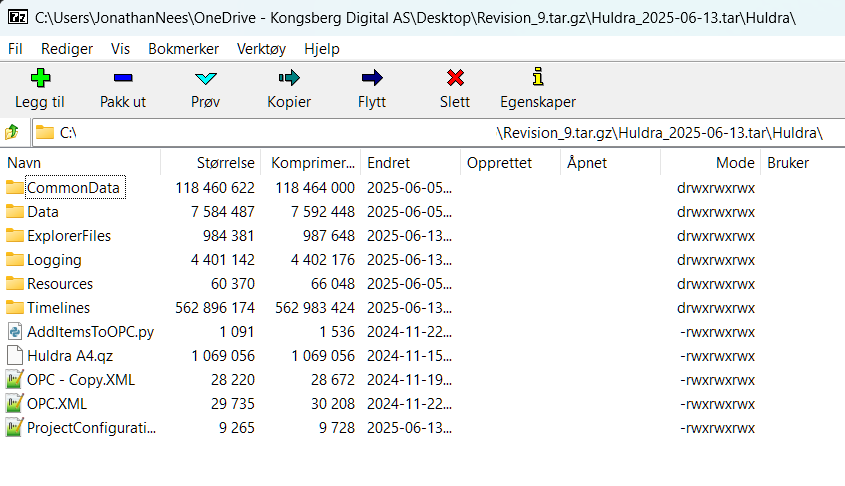

Several places in the What-If Configuration Dialog and in the admin portal allow the user to download simulation files.

When pressing on a corresponding download button, Kognitwin will in the background create an archive for downloading. Depending on the size of the files that are to be downloaded, this may take some time.

Once the archive is ready, the user might be prompted to select a location for saving the file, or the browser will use the default download location.

Once the download is complete, the user should have a .tar.gz archive available. We recommend using 7zip in windows for browsing and extracting files from the archive.

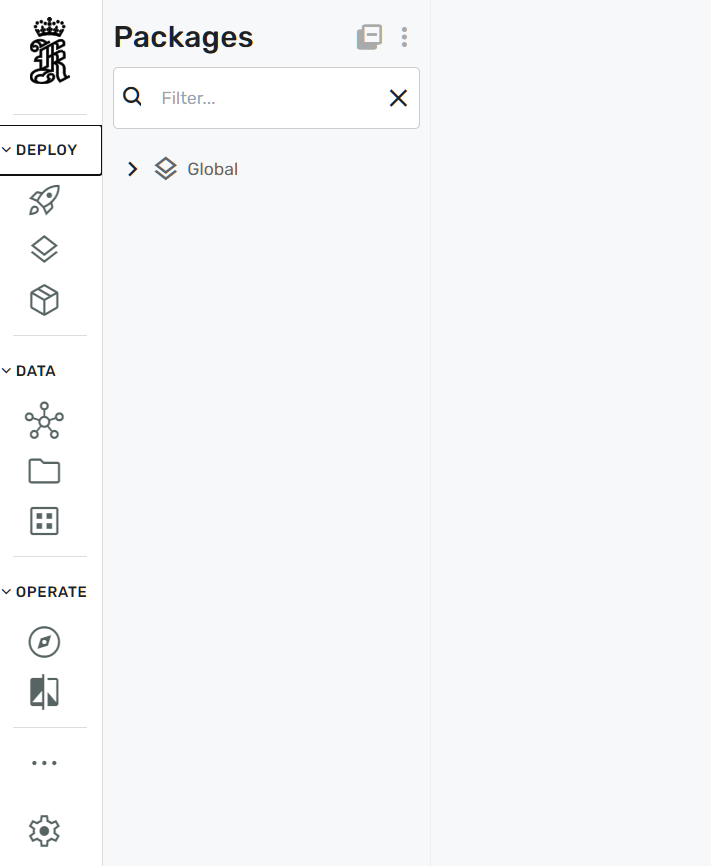

Admin Portal¶

To administrate simulation projects and simulation instances in Kognitwin, the user will need to have a dedicated admin access. Once a user has been granted the administrator rights, the so called "portal" can be accessed by appending "/portal" to your Kognitwin instance URL (for example kdi.kognitwin.com/portal).

The main menu bar on the left of the portal contains different categories and options.

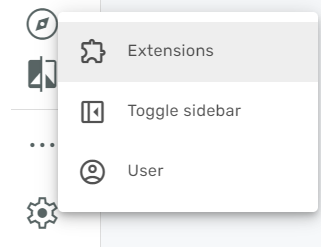

To enable simulation specific configuration, the simulation extension needs to be enabled from the settings menu. This can be achieved by clicking on the cog-wheel and then selecting extensions:

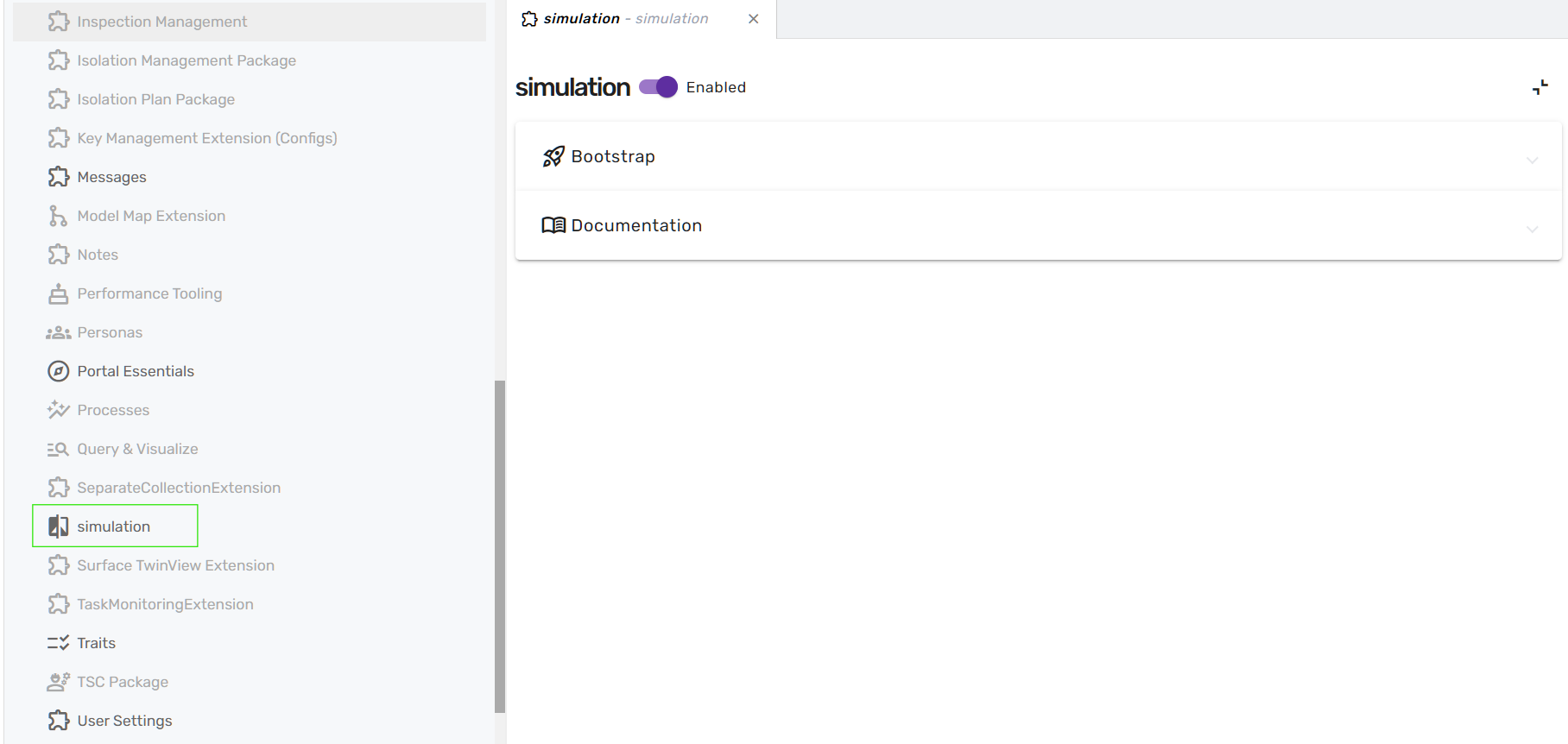

In the new menu stripe that opens, the Simulation category needs to be selected from the list. Clicking on the simulation menu entry will then allow the user to enable the simulations extension by moving the slider to "enabled"

Once the simulation extension is enabled, the user needs to refresh the website from the browser and a new main Simulation menu entry will appear under the "operations" section.

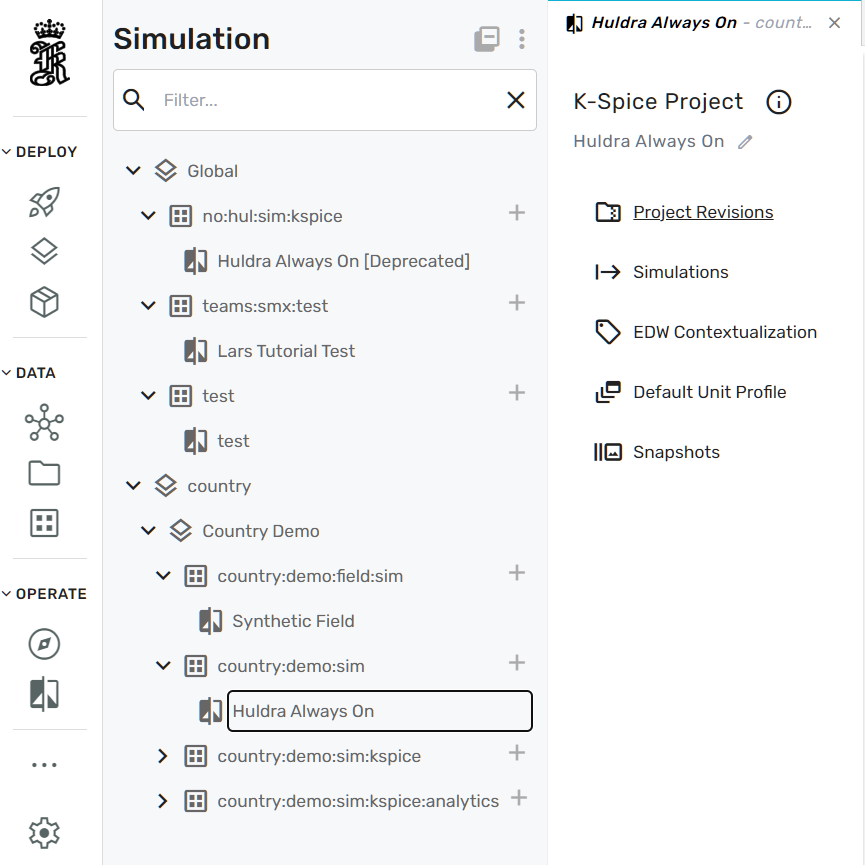

In this menu, a simulation project needs to be selected from the navigation tree (in this example case "Huldra Always On"). Now, the simulation project can be administered using the following configuration categories:

- Project Revisions

- Simulations

- EDW Contextualization

- Default Unit Profile

- Snapshots

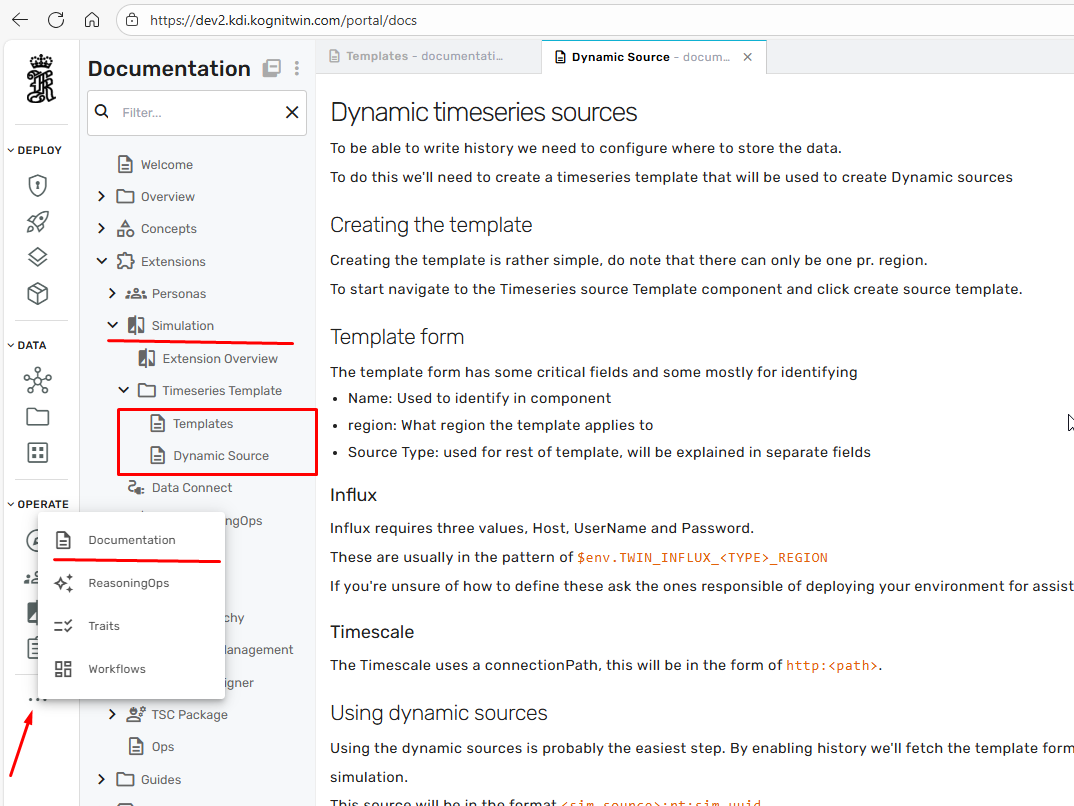

More detailed information on the functionality of the different administration workflows can be accessed directly from the portal: